- Slump loss, reduced setting time, plastic shrinkage, and thermal cracking are common in hot weather.

- Adjusting the mix, controlling temperature, timing the pour, protecting the surface, and proper curing all contribute to a resilient driveway.

Pouring a concrete driveway in Minnesota’s hot summer weather requires careful consideration. Concrete mix, timing, temperature, and protection can all affect the final product’s integrity. However, there is such a thing as too hot and too humid when it comes to concrete, so there are outside variables to consider and best practices to follow for a quality result.

Concrete mix, temperature, timing, and surface protection can all affect the integrity of the concrete being poured. We will explore why and how these affect concrete pouring as well as best practices to help you pour concrete that will last. Whether you’re a contractor, homeowner, or DIYer, this blog will help you pour quality concrete, regardless of the heat.

Understanding Hot Weather Concreting

Definition of Hot Weather Concreting

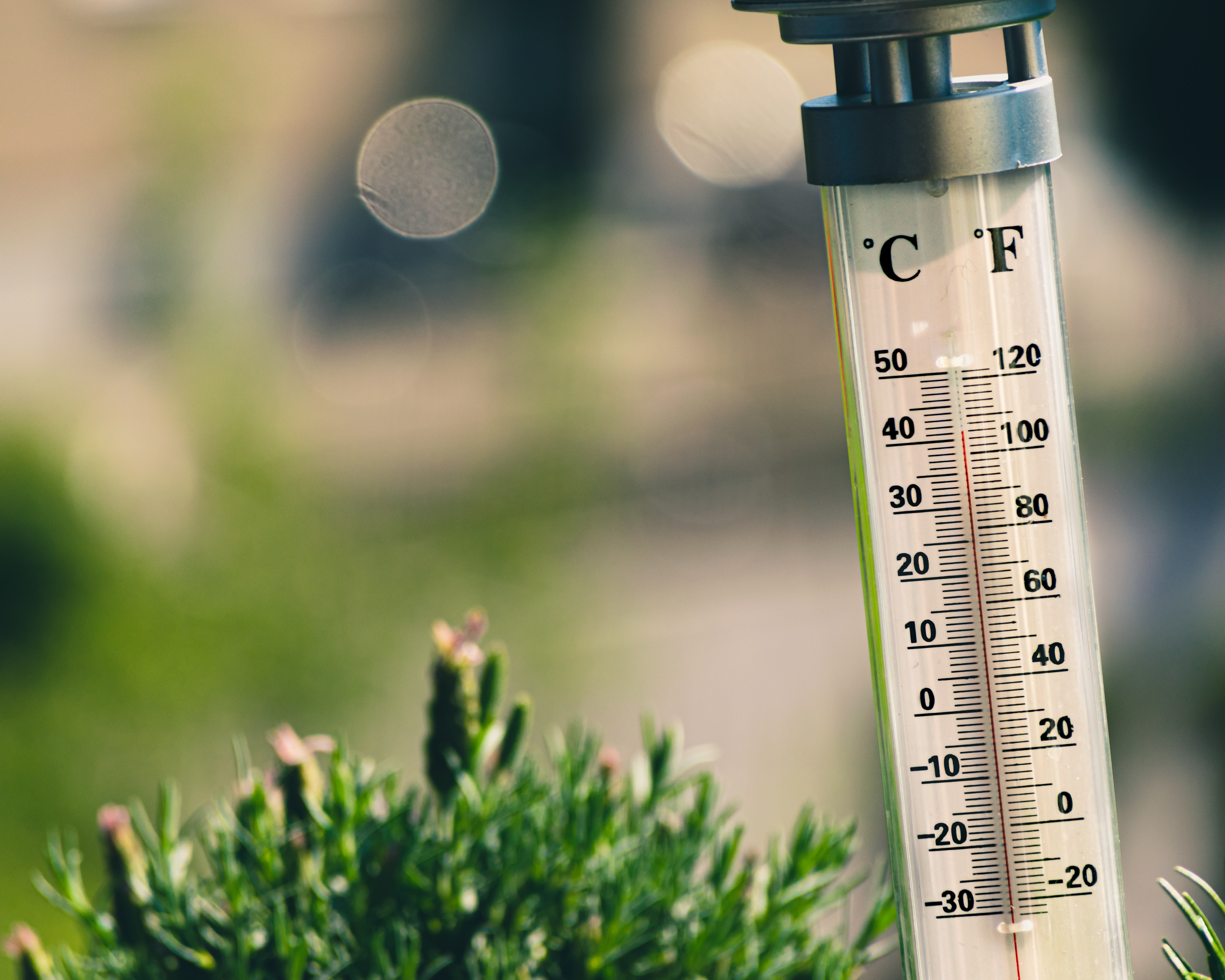

Hot weather concreting is when you pour concrete in hot weather, but what does “hot” mean? According to The Committee Report ACI 305R-99, Hot Weather Concreting, is any combination of the following conditions:

- High ambient temperature

- High concentrate temperature

- Low relative humidity

- Wind speed

- Solar radiation

Basically, the above means any circumstances where the heat could effect the integrity of the concrete. For our purposes, 80° is a good rule of thumb to think about hot concreting best practices.

This kind of weather can happen really anywhere at any time, but for us Midwesterners, we mostly see it in our summers. Thankfully, we tend to have more humid summers to lessen the risk of damage to concrete while pouring, but there are still other challenges we face.

Common Challenges in Hot Weather Concreting

1. Slump Loss

One of the biggest challenges in hot weather concreting is the increased demand of water from the concrete mix. High temperatures cause the concrete to lose moisture quickly (evaporation), meaning the water content in the cement mix decreases, leading to a decrease in slump. This slump loss makes the concrete more challenging to handle and can cause weaker bonds between the concrete and the reinforcement.

To help keep your slump, you can adjust your concrete mix to help the increased need for water. There are additives available to account for this, making the concrete more workable, reducing evaporation, and supporting proper curing. If you lose a lot of slump, you can add a small amount of water or adjust your mix proportions as you go.

2. Less Setting Time

Hot weather, especially high temperatures and low humidity, can quicken the setting time of concrete, making it challenging to handle, compact, and finish in time. This reduces the amount of working time and can lead to surface deformities and unevenness if the crew does not work efficiently enough.

This can also affect curing. A concrete slab sets when the water absorbs into the concrete and crystals form. Cooler concrete means the process takes longer, allowing more time for those crystals to form and strengthen. Higher temperature means less time for hydration and crystal formation, resulting in weaker concrete.

Scheduling the pour during the coolest part of the day can help minimize the risk of less setting time.

3. Plastic Shrinkage and Thermal Cracking Risks

Plastic shrinkage is when the moisture on the surface of poured concrete evaporates faster than the bleed water in the concrete can rise to the surface. This moisture loss happens quickly in higher temperatures, causing tensile stresses, which lead to this shrinkage, and then cracks on the surface.

Thermal cracking is when there is a large difference in the temperatures between the concrete itself and its surroundings. High temperatures can cause fast surface drying, leading to higher temperatures in the concrete, but cooler temperatures at the surface. This temperature differential can cause internal stress on the concrete and lead to cracking.

To reduce the risk of cracking, you can protect the concrete surface from too much moisture lost. Techniques like covering the concrete with damp burlap or plastic sheeting can help retain moisture and prevent cracking. Also, avoiding direct sunlight(when possible) and high winds during the curing process can reduce surface drying and cracking.

4. Air-Entrained Content

Air-entrained concrete is used more in cold climates to improve freeze-thaw resistance. However, in hot weather concreting, controlling the air-entrained content can be challenging. The high temperatures, reduced workability, and mixing can make it difficult to maintain the air content in the concrete.

Adjustments to your concrete mix or the addition of additives can help reach the level of air content necessary.

Best Practices for Pouring Concrete in Hot Weather

1. Adjust the Concrete Mix

A well-designed mix helps counteract the effects of high temperatures, improves workability, and long-term performance in hot weather conditions. Choose concrete materials that have a good track record in hot weather conditions. Using additives, like fly ash or slag, can enhance workability, reduce water demand, and minimize heat during hydration.

2. Control Concrete Temperature

Controlling the concrete temperature extends the working time and reduces the risk of premature hardening, ensuring a smoother process. Take measures to manage the concrete temperature during mixing, transportation, and placement. This includes using chilled water, ice, or insulating materials to cool the mix and prevent rapid setting.

3. Optimize Timing and Scheduling

Pouring during cooler hours helps maintain workability, gives you more time for placement and finishing, and reduces the risk of rapid moisture loss. Plan your concrete pour for the coolest part of the day, typically early morning or late evening, or the coolest days. Avoid pouring during the hottest hours to minimize the impact of high ambient temperatures.

4. Protect the Concrete Surface

Protecting the surface prevents cracks caused by shrinkage and thermal stress, and it promotes proper hydration, leading to improved strength and durability. Prevent excessive moisture loss by covering the concrete with damp burlap, plastic sheeting, or using curing compounds. These measures help retain moisture and prevent the surface from drying too quickly.

5. Proper Curing Methods

Proper curing ensures the concrete develops optimal strength, reduces the risk of cracking, and improves its overall durability, even in hot weather conditions. Make sure to execute appropriate curing practices, like continuous sprinkling or using curing blankets, to maintain the moisture content and temperature of the concrete during the early stages of hydration.

6. Monitor and Adjust Slump

Keeping the proper slump ensures the concrete is easy to work with, helps with consolidation, and minimizes issues related to water demand and workability in hot weather. Regularly check the slump of the concrete during placement. Adjust the mix proportions or take necessary steps to maintain the desired slump and workability.

Conclusion

Pouring concrete in hot weather may seem straightforward, but there are important considerations and best practices to ensure a successful outcome. By understanding the effects of temperature, timing, and surface protection, we can overcome the challenges of hot weather concreting and pour high-quality concrete that will stand the test of time.

By following the above best practices, whether you’re a contractor, homeowner, or DIYer, you can confidently pour concrete in hot weather conditions and achieve exceptional results. Remember, understanding the impact of temperature and implementing the right techniques will help you pour quality concrete that withstands the challenges of hot weather.

For expert service, choose Cornerstone Concrete LLC. Get a free estimate and explore our financing options. Contact us for assistance.